Fundamentals of DevOps

Process

A Product Managers Scenario

Welcome back. In this article, we shift our focus within DevOps to explore a Product Manager’s scenario, placing a strong emphasis on LEAN principles. Discover how a renewed focus on customer needs can transform processes and drive continuous improvement.

Imagine a thriving team with robust processes, excellent automation, and strong internal engagement. Despite these operational strengths, both internal and external customers remain dissatisfied. The root cause? The team was not fully aligned with the customers’ true needs.

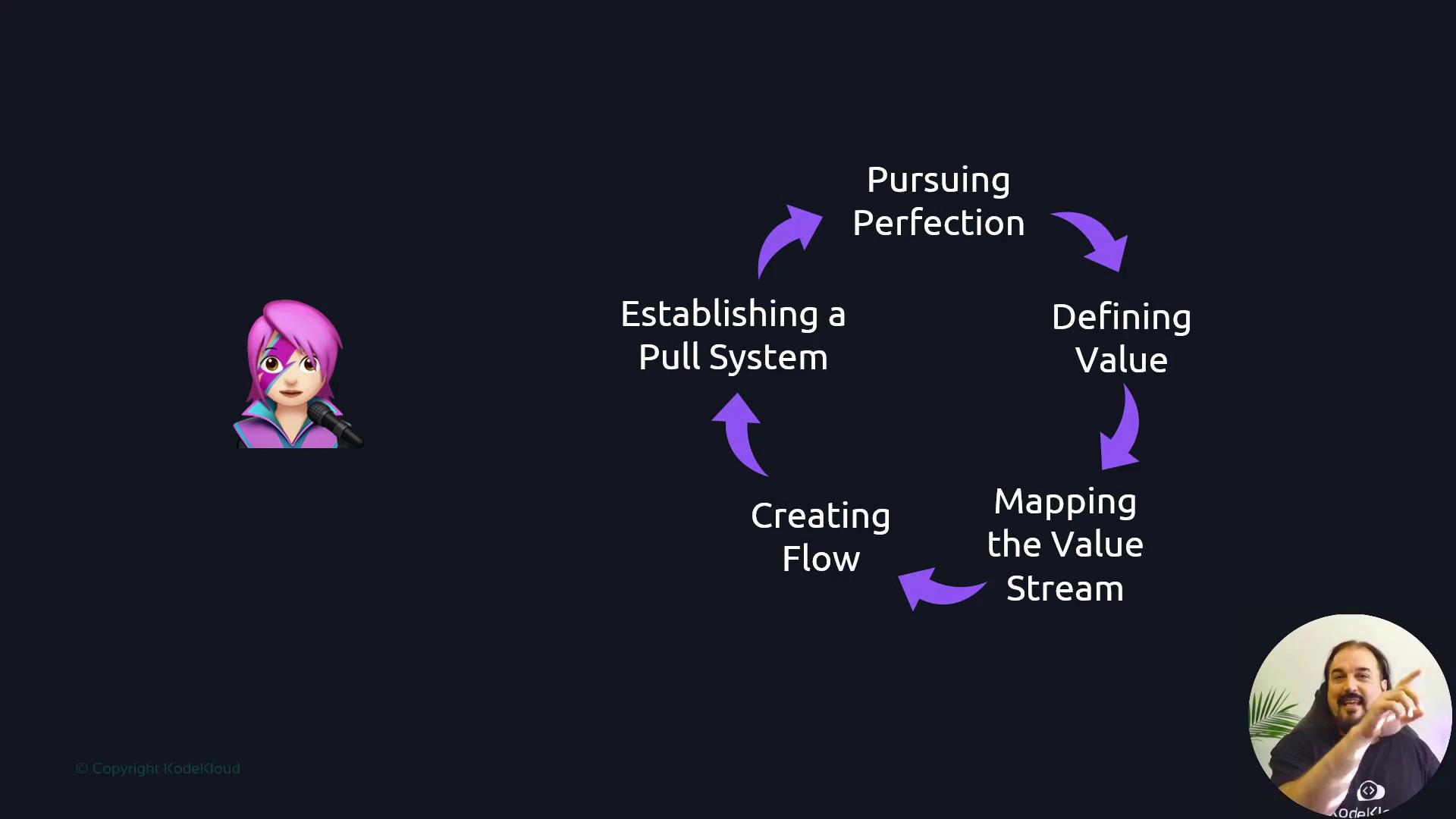

Peter, the lead product manager, recalled his training in LEAN principles during his DevOps journey. These principles focus on enhancing processes by centering them around customer needs. He gathered his team to revisit the core fundamentals of LEAN:

- Defining value from the customer’s perspective.

- Mapping the value stream to understand how that value is delivered.

- Creating a smooth flow by removing obstacles.

- Establishing a pull system where work is driven by actual demand.

- Pursuing perfection through continuous improvement.

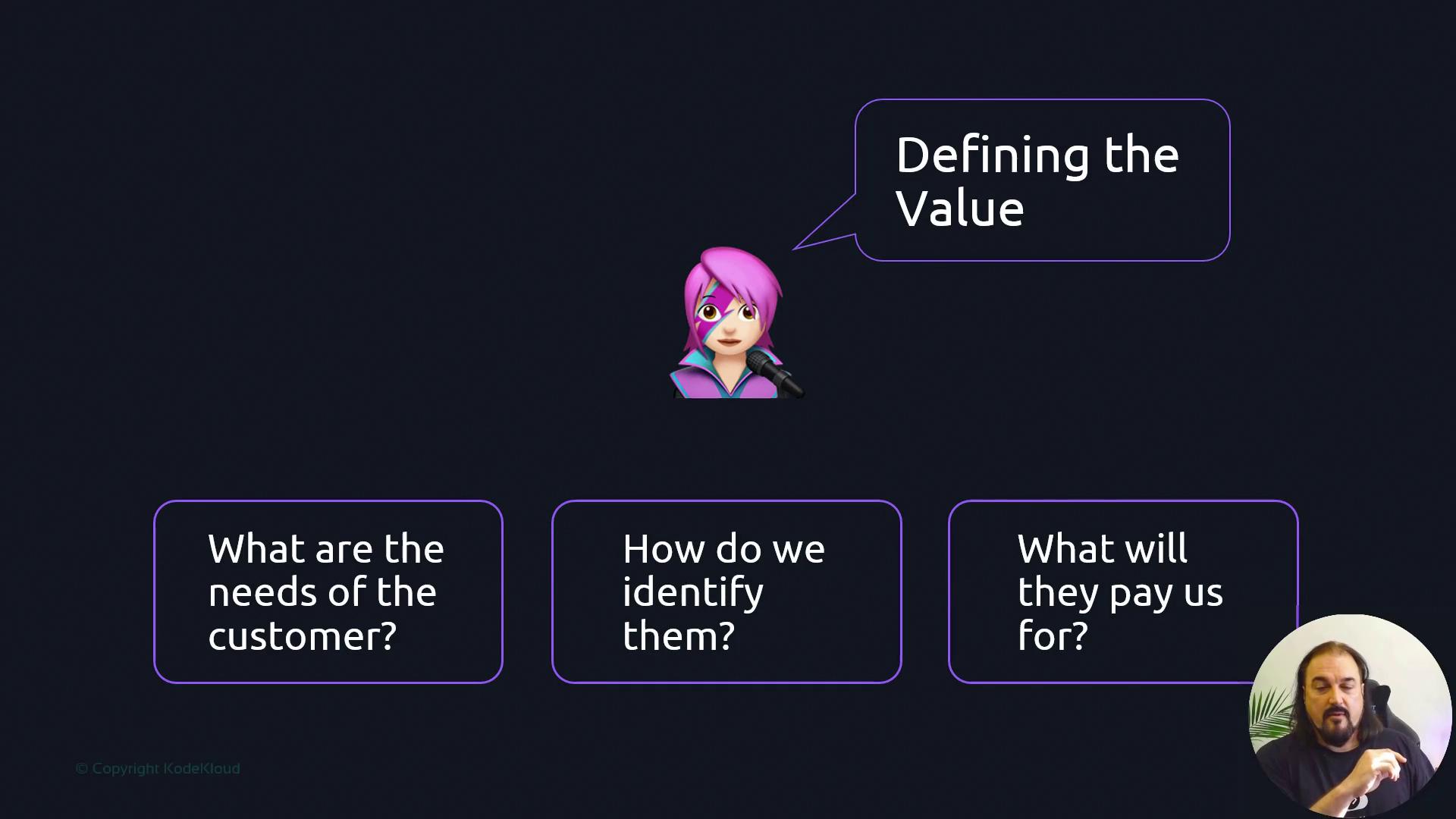

Peter began by exploring what constitutes value from the customer’s standpoint. He challenged his team with questions such as: What are our customers’ real needs? What will they actually pay for?

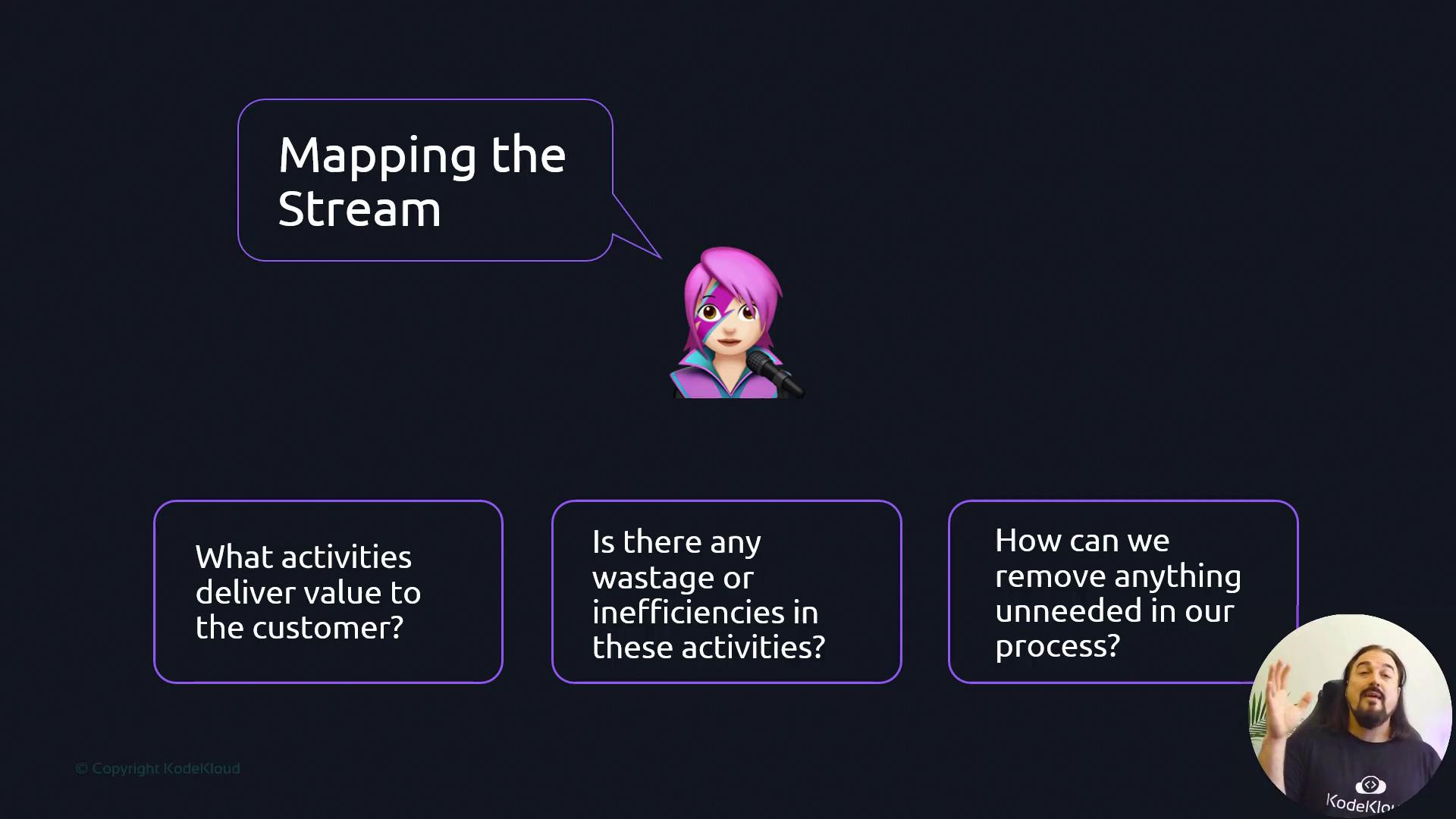

Next, the team turned its attention to mapping the value stream. This crucial step involved identifying every activity that contributes to customer value and scrutinizing each process to uncover inefficiencies or non-value-adding steps, thereby eliminating waste.

Peter then highlighted the importance of creating flow within the value stream. He encouraged the team to evaluate which activities truly added value and to remove any processes that obstructed the smooth delivery of that value.

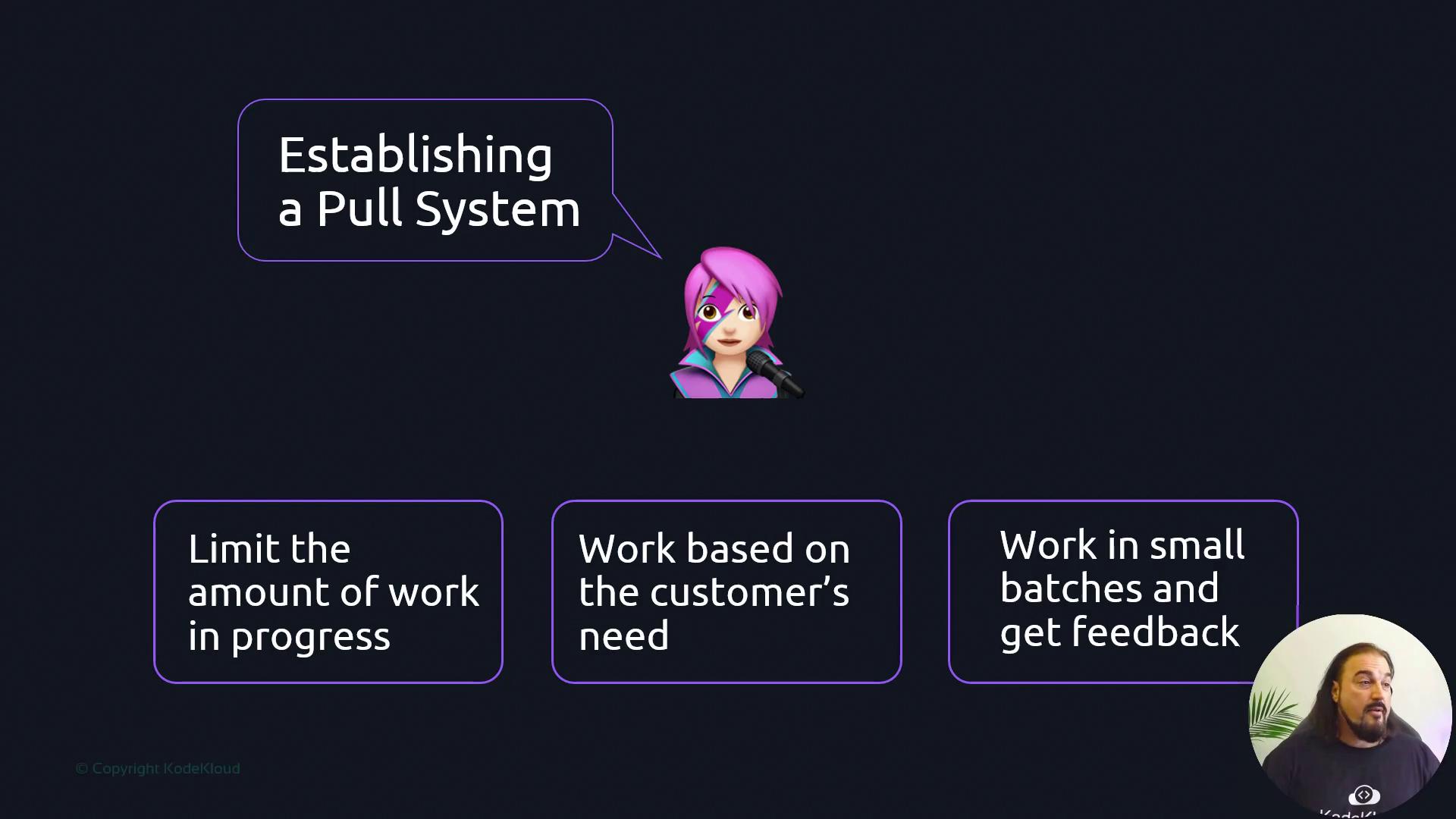

Following this, he introduced the concept of the pull system. This system emphasizes three key principles:

- Limit the amount of work in progress (WIP).

- Base work on genuine customer demand.

- Organize work in small batches to enable rapid feedback.

Key Insight

Pursuing perfection is not about immediate, radical changes. It is a continuous journey of incremental improvements that collectively lead to significant gains over time.

Finally, Peter underscored the most vital principle: pursuing perfection. This means persistently eliminating waste, refining processes, upgrading technology, and enhancing skills through daily incremental improvements.

With these LEAN principles in action, the team realigned its processes with customer needs. They defined value, mapped the value stream, removed bottlenecks to flow, adopted a pull system, and continually sharpened their operations. As a result, the previously dissatisfied customers—both internal and external—gradually became delighted and fully engaged with the product and its delivery.

Summary of Key Points

- LEAN Thinking Origins: Rooted in Toyota’s manufacturing system, LEAN thinking focuses on holistic process improvement.

- Core Principles: The LEAN methodology incorporates defining customer value, mapping the value stream, creating flow, establishing pull systems, and relentlessly pursuing perfection.

- DevOps Connection: In the DevOps realm, these principles manifest as small batch workflows, rapid feedback cycles, and the active elimination of inefficiencies to maintain smooth operational flow.

Thank you for reading this article. We hope these insights into LEAN principles and their application within a DevOps framework help you understand the importance of aligning team processes with customer needs. We'll see you next time.

Watch Video

Watch video content